NewsDetails

In-Depth Analysis of Seamless Steel Pipe Mechanical Properties: How Tensile Strength and Toughness Safeguard Industrial Operations

author:Zhantong time:2025-07-09 16:24:37 Click:104

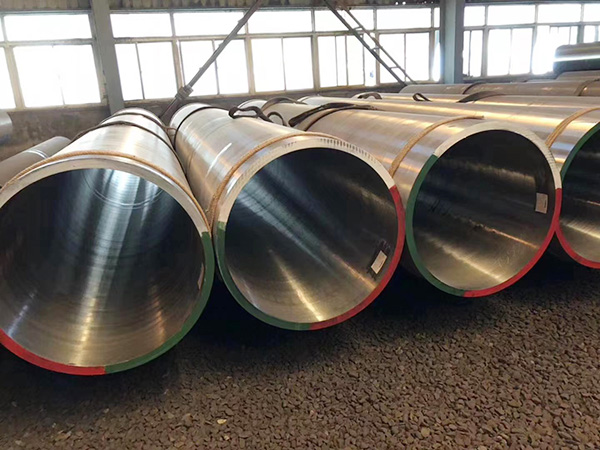

In complex industrial systems, seamless steel tubes serve as the lifelines—carrying fluids, transmitting force, and supporting structural integrity. Among their various properties, tensile strength and toughness play a decisive role in ensuring operational safety and long-term reliability. These mechanical attributes form the foundation of efficient, high-performance industrial production.

Tensile Strength: The First Line of Defense in Pressure-Bearing Applications

What Is Tensile Strength and Why Does It Matter?

Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before breaking. For seamless steel tubes used in high-pressure environments—such as oil and gas transmission—high tensile strength is critical. Without it, pipes may deform under internal pressure or rupture, posing serious safety risks and potentially leading to resource leakage or equipment failure.

In high-temperature and high-pressure systems like boilers, seamless pipes are responsible for steam conduction. Pipes with adequate tensile strength can resist mechanical fatigue and thermal cycling, thus maintaining operational integrity over time.

Key Factors Affecting Tensile Strength

Chemical Composition: Carbon content enhances strength but must be controlled to preserve ductility. Alloying elements such as chromium, nickel, and molybdenum help form strengthened microstructures and improve tensile performance.

Processing and Heat Treatment: Hot rolling refines the internal grain structure and eliminates defects, while cold rolling increases strength by refining grains. Quenching and tempering techniques allow for controlled mechanical behavior, boosting both strength and reliability.

International studies confirm the correlation between alloy composition, thermal treatment, and the resulting tensile behavior—offering solid theoretical guidance for performance optimization.

Toughness: Essential for Impact Resistance and Sudden Load Absorption

What Is Toughness and Why Is It Crucial in Industry?

Toughness is the ability of a material to absorb energy and deform plastically before fracturing. seamless steel tubes frequently face impact loads and dynamic stresses—whether from startup surges, vibration, or seismic activity. High toughness enables a pipe to absorb shock without breaking, preventing sudden system failures.

For example, in structural applications and major infrastructure projects, seamless pipes must provide seismic resistance and load-bearing capacity. High-toughness materials allow frameworks to remain intact under stress, safeguarding critical infrastructure from catastrophic collapse.

Factors That Influence Toughness

Environmental Temperature: As temperature drops, steel toughness typically decreases. In extremely cold environments—like polar regions or high-altitude zones—standard pipes may suffer brittle failure. Special seamless pipes with low-temperature toughness are required in these applications.

Grain Structure: Fine and uniform equiaxed grains impede crack propagation. Conversely, coarse grains or internal defects reduce impact resistance significantly.

Research shows that adjusting cooling rates and heat treatment parameters improves microstructural uniformity and toughness, enabling pipes to perform reliably in demanding environments.

Balancing Tensile Strength and Toughness: The Core of Industrial Steel Performance

In practice, tensile strength and toughness must be balanced. Excessive focus on strength can result in brittleness, while prioritizing toughness alone may compromise load-bearing capability.

Take aerospace manufacturing as an example: pipes must endure extreme mechanical stress during flight while withstanding constant vibration. Engineers achieve this by fine-tuning alloy ratios and using advanced manufacturing techniques to develop seamless steel tubes with both high strength and superior toughness—ideal for critical applications.

Our Competitive Edge: Delivering High-Performance Steel for Demanding Industries

As a trusted supplier of seamless steel tubes, we understand the importance of mechanical properties in ensuring operational safety. We rigorously control raw materials, apply optimized alloying practices, and use advanced heat treatment methods to enhance both tensile strength and toughness across our product range.

Each pipe undergoes comprehensive mechanical testing, including tensile strength evaluation, Charpy impact testing, and hardness measurement. Our products meet international standards and can be customized to client-specific performance requirements. They are widely used in industries such as oil & gas, boiler manufacturing, and civil infrastructure—offering high strength, stability, and long-term reliability.

International References

1.Materials Science and Engineering: A

A leading journal covering empirical studies on the relationship between alloy composition, microstructure, and tensile strength in metallic materials.

2.Journal of Materials Processing Technology

Focuses on processing methods and thermal treatment technologies that impact the mechanical performance of industrial steel products, including seamless pipe manufacturing.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province