NewsDetails

How Seamless Steel Tubes Perform in Offshore Deep-Sea Pipeline Systems

author:Zhantong time:2025-08-18 15:48:40 Click:156

Why Seamless Steel Tubes Are Ideal for Deep-Sea Energy Transmission

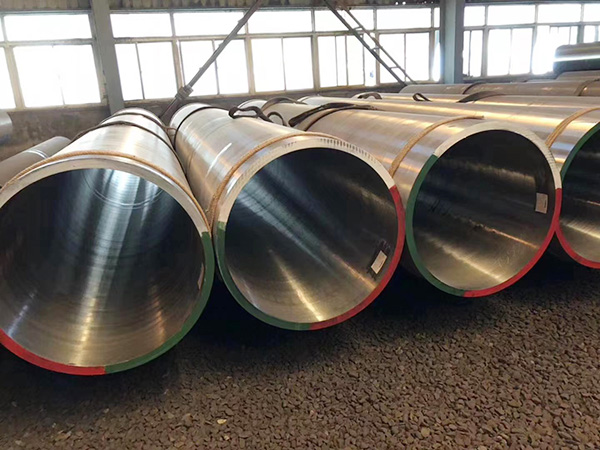

In the offshore oil and gas industry, pipeline systems must perform reliably under extreme underwater conditions. Deep-sea installations are subjected to high external pressures, dynamic movement, and corrosive environments that challenge even the most robust materials. Seamless steel tubes stand out as a proven solution, offering exceptional mechanical strength and uniformity.

Their structure, free of longitudinal welds, eliminates weak points and ensures reliable performance in subsea energy transport networks.

Advantages of Seamless Design in Subsea Applications

Seamless steel tubing is manufactured through a process that avoids any welding, resulting in continuous, homogenous pipe walls. This seamless design enhances performance in several critical ways:

·Enhanced Structural Uniformity: With no welded seams, these tubes distribute stress evenly, reducing the risk of localized failure.

·Superior Integrity Under Pressure: Ideal for deep-water depths where pressure increases dramatically.

·Consistent Wall Thickness: Improves fit, strength, and longevity in long-distance pipeline layouts.

These benefits collectively make seamless steel tubes the backbone of modern offshore energy transmission.

Withstanding Pressure and Cyclic Loading

Pipelines in deep waters endure massive internal product pressure and external oceanic pressure. The seamless construction allows steel tubes to handle such forces without deformation or rupture.

Additionally, ocean currents, tides, and seabed movement exert constant cyclical stress. The metallurgical consistency of seamless tubes gives them a higher resistance to fatigue, reducing the likelihood of long-term structural breakdowns.

Thermal Stability and Dimensional Consistency

In subsea environments, temperature shifts can be drastic—from freezing seawater to the elevated temperatures of transported hydrocarbons. Seamless steel tubes maintain mechanical reliability across these fluctuations.

Unlike composite or welded options, seamless tubes are less susceptible to thermal distortion, which helps preserve joint alignment, internal coating integrity, and stress distribution.

Corrosion Resistance in Marine Environments

Corrosion is one of the most common threats to offshore pipeline infrastructure. Seamless steel tubes—especially those fabricated from corrosion-resistant alloys—perform exceptionally well against threats like:

·Chloride-induced stress cracking

·Seawater pitting corrosion

·External microbial-influenced corrosion (MIC)

This makes them an optimal choice for long-term, high-integrity fluid transport systems beneath the sea.

Optimizing Installation Efficiency and Maintenance

One of the operational advantages of seamless steel tubes lies in their precision and ease of deployment. Their consistent dimensional tolerances reduce complexity during joint preparation, welding, and subsea installation.

Moreover, because of their enhanced durability, maintenance interventions are minimized. Over time, this reduces both operating costs and system downtime—key factors for oil and gas operators balancing safety and efficiency.

Standards That Ensure Performance in Harsh Environments

To ensure safe and reliable application, seamless tubes for offshore systems are certified under international standards, including:

·API 5L – Petroleum and natural gas industries – steel pipe for pipeline transportation systems

·ASTM A106 / A53 – Seamless carbon steel pipe for high-temperature service

·ISO 3183 – Petroleum and natural gas industries – Steel pipe for pipelines

Compliance with these standards ensures materials meet the required thresholds for strength, resilience, and safety.

Key Design Considerations in Deep-Sea Projects

Selecting the appropriate seamless steel tube requires careful planning. Factors influencing tube performance in deep-sea contexts include:

·Depth-related pressure and required wall thickness

·Environmental risks like corrosion and temperature cycling

·Load-bearing needs for long-term fatigue resistance

·Compatibility with joining methods and protection systems

Engaging with experienced engineers during material selection can help tailor the tubing solution for specific environmental and project needs.

Final Thoughts: Seamless Steel Tubes as the Offshore Standard

Offshore pipelines serve as the circulatory system of modern energy production. In deep-sea environments, even minor flaws can result in costly leaks or major failures. That’s why seamless steel tubes have become the trusted choice for subsea pipeline construction.

With exceptional durability, pressure tolerance, and environmental stability, these tubes ensure both safety and performance in the world’s most challenging conditions.

Summary

·Seamless steel tubes offer unmatched performance in deep-sea oil and gas transport.

·They provide superior pressure capacity, resistance to corrosion, and reliability over time.

·Their seamless structure reduces the risk of failure and simplifies installation and maintenance.

·Engineering standards and proper selection are key to maximizing their offshore performance.

References

GB/T 7714:Vishnuvardhan S, Ramachandra Murthy A, Saravanan M, et al. Crack Growth Life Prediction in API 5L X46 Grade Steel Pipes Subjected to Cyclic Internal Pressure[C]//National Conference on Reliability and Safety. Singapore: Springer Nature Singapore, 2022: 83-97.

MLA:Vishnuvardhan, S., et al. "Crack Growth Life Prediction in API 5L X46 Grade Steel Pipes Subjected to Cyclic Internal Pressure." National Conference on Reliability and Safety. Singapore: Springer Nature Singapore, 2022.

APA:Vishnuvardhan, S., Ramachandra Murthy, A., Saravanan, M., & Gandhi, P. (2022, March). Crack Growth Life Prediction in API 5L X46 Grade Steel Pipes Subjected to Cyclic Internal Pressure. In National Conference on Reliability and Safety (pp. 83-97). Singapore: Springer Nature Singapore.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province