NewsDetails

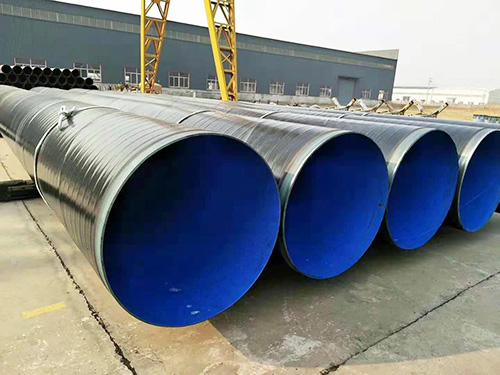

TPEP Pipe Coating Technology: A Key Innovation for Long-Distance Oil Pipeline Protection

author:Zhantong time:2025-10-19 17:53:03 Click:176

Why TPEP Pipes Matter for Energy Transport

The growing complexity of global oil infrastructure demands pipeline systems that can withstand corrosion, temperature shifts, and mechanical stress for decades. In this environment, TPEP pipes—short for Three-Layer Polyethylene/Polypropylene Coating Pipes—have become a benchmark material for long-distance oil pipelines.

Their multi-layer coating structure provides exceptional resistance to moisture, oxidation, and external impact. Supported by China’s large-scale production and bulk supply networks, TPEP pipes are increasingly favored for modern energy projects that prioritize safety, cost efficiency, and longevity.

1. Understanding TPEP Pipe Coating

TPEP coating technology integrates three key protective layers on a steel pipe base, each performing a distinct role in safeguarding the metal from degradation:

1.Fusion Bonded Epoxy (FBE) Inner Layer:

Acts as the foundation, chemically bonding to the steel and blocking corrosion.

2.Adhesive Intermediate Layer:

Ensures strong cohesion between the epoxy and outer polymer coating.

3.Outer Polyethylene or Polypropylene Layer:

Shields against physical impact, UV radiation, and environmental wear.

This multi-layer approach creates a tightly bonded, impermeable system capable of enduring soil pressure, water immersion, and high-temperature operation. For cross-country or underwater pipelines, TPEP pipes deliver unmatched structural stability.

2. Engineering Advantages of TPEP Coating

Long-distance oil pipelines face constant exposure to corrosive substances, temperature variations, and soil chemistry. The TPEP coating system addresses these challenges through several critical features:

·Outstanding Corrosion Resistance:

The epoxy base layer prevents direct metal contact with oxygen and moisture.

·Superior Adhesion and Flexibility:

The adhesive layer prevents coating detachment during thermal expansion or bending.

·High Impact Strength:

The polymer layer absorbs mechanical stress from handling, trenching, or backfilling.

·Wide Temperature Range Performance:

TPEP coatings remain effective from arctic cold to desert heat.

·Reduced Maintenance Costs:

Its durability reduces inspection frequency and long-term maintenance expenses.

These characteristics make TPEP pipes the preferred choice for modern oil and gas pipeline systems extending hundreds or even thousands of kilometers.

3. The Manufacturing Process: Precision and Consistency

Producing TPEP-coated pipes requires advanced coating equipment, precise temperature control, and rigorous inspection standards. The general process includes:

1.Steel Pipe Preparation:

Cleaning and blasting remove oxidation, rust, and contaminants to ensure proper adhesion.

2.Epoxy Application:

The FBE layer is electrostatically sprayed to form a dense, uniform coating.

3.Adhesive and Polymer Extrusion:

Layers are successively applied using heat fusion technology to create a seamless protective film.

4.Cooling and Finishing:

Controlled cooling solidifies bonding between layers.

5.Quality Testing:

Non-destructive tests check for coating thickness, uniformity, and resistance to impact and voltage.

China TPEP pipe manufacturers are globally recognized for combining these technologies with bulk supply capacity, enabling large-scale infrastructure delivery while meeting API, DIN, and ISO standards.

4. Why TPEP Pipes Outperform Conventional Coating Systems

While traditional coatings such as bitumen, 2PE, or 3PE provide limited protection, TPEP coating achieves a superior balance of strength and flexibility. Major comparative advantages include:

·Improved bonding strength and longevity under fluctuating temperature conditions.

·Better mechanical performance, preventing coating rupture during pipeline handling.

·Resistance to soil movement and groundwater chemicals, ensuring stability in buried installations.

·Smooth surface characteristics, which minimize friction and enhance oil flow efficiency.

This combination of physical and chemical protection ensures TPEP pipes perform reliably across complex terrains and long service cycles.

5. China’s Role in Global TPEP Pipe Supply

With advanced metallurgical industries and automated coating facilities, China has become a key producer of TPEP pipes for global markets. Local manufacturers leverage integrated steel processing and coating lines to offer bulk supply at competitive cost while maintaining strict international quality standards.

Advantages of China’s supply chain include:

·High-capacity production lines capable of manufacturing large-diameter coated pipes.

·Customizable coating thickness and material combinations for specific climates or terrains.

·Comprehensive testing and certification according to global specifications.

This ensures that China-based suppliers can support both domestic oil transport systems and overseas energy infrastructure projects efficiently.

6. Technological Innovations and Future Development

The future of TPEP coating technology lies in materials innovation and sustainable production. Emerging research focuses on:

·Eco-friendly epoxy resins with lower volatile organic compounds (VOCs).

·Nanocomposite-enhanced coatings to further improve barrier performance.

·Smart inspection systems using real-time sensors to monitor coating condition during operation.

·Recyclable materials that support circular economy practices in the steel and energy sectors.

These advancements will further strengthen the reliability of TPEP pipes, ensuring they continue to meet the stringent demands of next-generation oil pipelines.

Conclusion: TPEP Pipes — Strength, Longevity, and Reliability Combined

From the scorching deserts of the Middle East to the frozen tundra of Siberia, TPEP pipes have proven their ability to withstand diverse environmental challenges. Their triple-layer protection, exceptional durability, and corrosion resistance make them the foundation of safe and efficient oil transportation systems.

With China manufacturers offering bulk supply capacity and continuous coating innovation, TPEP pipes stand as the preferred material for long-distance pipeline projects worldwide—ensuring that vital energy resources flow securely and efficiently into the future.

References

GB/T 7714:Ma L, Zhang P, Li W, et al. Research progress on coating technology for oil and gas pipelines[C]//Journal of Physics: Conference Series. IOP Publishing, 2025, 2971(1): 012006.

MLA:Ma, Lihui, et al. "Research progress on coating technology for oil and gas pipelines." Journal of Physics: Conference Series. Vol. 2971. No. 1. IOP Publishing, 2025.

APA:Ma, L., Zhang, P., Li, W., Liu, X., Yue, Y., Liu, J., ... & Bian, J. (2025, February). Research progress on coating technology for oil and gas pipelines. In Journal of Physics: Conference Series (Vol. 2971, No. 1, p. 012006). IOP Publishing.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province