NewsDetails

TPEP Pipe Manufacturing Process Explained: Coating, Fusion, and Inspection

author:Zhantong time:2026-01-19 16:28:56 Click:166

What Are TPEP Pipes?

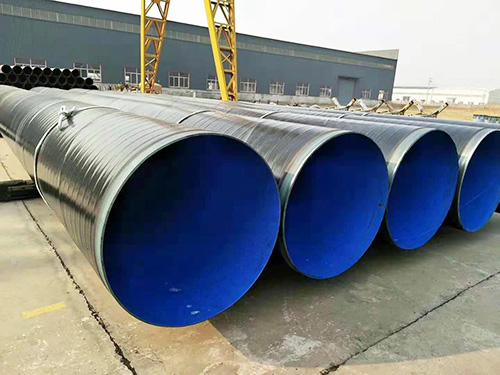

TPEP Pipes are advanced steel pipelines protected by a three-layer polyethylene coating system designed to improve corrosion resistance, mechanical protection, and service life. The structure normally consists of an inner fusion-bonded epoxy layer, an adhesive middle layer, and an outer polyethylene layer.

Compared with traditional coated pipes, TPEP pipes provide enhanced bonding strength between steel and polymer materials. This structure allows pipelines to operate reliably in buried, underwater, and chemically aggressive environments. A professional TPEP pipes manufacturer relies on standardized production lines to ensure each layer performs as a single integrated system rather than separate coatings.

Through controlled factory production, TPEP pipes achieve consistent thickness, adhesion, and surface protection across large-scale pipeline projects.

Why TPEP Pipes Are Used in Modern Pipeline Systems

Pipeline systems are exposed to moisture, soil stress, temperature changes, and chemical attack. Without protection, steel pipelines quickly suffer from corrosion and mechanical damage.

TPEP Pipes are designed to reduce these risks by combining the corrosion resistance of epoxy with the flexibility and toughness of polyethylene. This layered structure protects the pipe body while maintaining strong adhesion to the steel substrate.

In water transmission, energy transport, and industrial fluid delivery, TPEP pipes reduce maintenance costs and extend service life. Manufacturer-controlled production ensures that protective performance remains stable from batch to batch for bulk supply projects.

Raw Materials and Surface Preparation

The manufacturing of TPEP Pipes begins with raw steel pipe selection and surface treatment. Steel pipes must meet dimensional and mechanical requirements before coating begins.

Surface preparation is critical. The pipe surface is cleaned using blasting to remove rust, oil, and scale. This process creates an ideal roughness profile for coating adhesion. Without proper preparation, even advanced coatings will fail prematurely.

Professional factory production systems monitor cleanliness and roughness parameters to ensure the epoxy layer bonds tightly to the steel surface.

Coating Process in TPEP Pipe Production

The coating stage defines the performance of TPEP Pipes. After preheating, fusion-bonded epoxy powder is sprayed onto the pipe surface. The heat causes the epoxy to melt and chemically bond to the steel.

Next, an adhesive layer is applied to connect the epoxy coating with the outer polyethylene. Finally, the polyethylene layer is extruded and wrapped around the pipe, forming a tough mechanical barrier.

This three-layer coating protects against corrosion, impact, and moisture penetration. Manufacturer production lines control coating thickness and uniformity to ensure each pipe section meets design standards.

Fusion Bonding Technology Explained

Fusion bonding is one of the core technologies behind TPEP Pipes. It allows epoxy materials to chemically integrate with the steel substrate rather than simply sitting on the surface.

During production, steel pipes are heated to a controlled temperature before epoxy application. When the epoxy contacts the hot surface, it melts, flows, and cures into a continuous protective film. This creates excellent adhesion and corrosion resistance.

Factory-controlled fusion processes ensure consistent bonding strength across large batch production, preventing coating delamination during transport or service.

Cooling and Dimensional Control

After coating and fusion, TPEP Pipes undergo cooling to stabilize the layers and lock in coating integrity. Cooling rates affect coating stress and final surface quality.

Dimensional control is equally important. The pipe must maintain roundness, straightness, and coating thickness consistency. Deviations can affect installation and sealing performance in pipeline networks.

A professional TPEP pipes manufacturer integrates sizing, inspection, and handling systems into factory production to protect coated surfaces while maintaining geometric accuracy for bulk supply delivery.

Inspection and Quality Testing Standards

Inspection ensures the reliability of TPEP Pipes before they leave the factory. Typical tests include coating thickness measurement, adhesion strength testing, holiday detection, and impact resistance evaluation.

Electrical holiday testing identifies pinholes or defects in the coating layer. Adhesion tests verify that epoxy and polyethylene remain bonded to the steel under stress.

Through systematic production inspection, manufacturers ensure that every batch of TPEP pipes meets protective performance requirements before shipment.

Manufacturer Production and Factory Supply Advantages

Choosing a professional TPEP pipes manufacturer provides consistency that cannot be achieved through scattered processing. Factory-scale production ensures repeatable coating performance, traceability, and quality documentation.

With organized factory supply, large infrastructure projects receive uniform pipes for stable installation and long-term operation. Bulk production also improves logistics efficiency and reduces project lead times.

Production transparency and process control further enhance reliability for water, energy, and industrial pipeline systems using TPEP pipes.

Applications of TPEP Pipes Across Industries

TPEP Pipes are widely used in municipal water transmission, industrial fluid transport, oil and gas infrastructure, and chemical pipelines. Their corrosion resistance and mechanical strength make them suitable for buried and underwater environments.

In long-distance pipelines, TPEP pipes minimize leakage risk and reduce maintenance frequency. Through professional manufacturer production and factory bulk supply, these pipes support stable performance in modern infrastructure networks.

Conclusion: Choosing Reliable TPEP Pipes

Understanding the TPEP pipe manufacturing process—from surface preparation and coating to fusion bonding and inspection—helps engineers select reliable pipeline solutions. TPEP pipes combine epoxy protection with polyethylene toughness for long-term corrosion resistance.

By working with suppliers backed by professional manufacturer production and dependable factory supply, projects gain consistent quality, stable performance, and reduced operational risk.

Ultimately, TPEP Pipes are not just coated steel—they are engineered systems designed to protect pipelines, improve durability, and support modern infrastructure efficiently.

References

GB/T 7714:Qian S, Cheng Y F. Degradation of fusion bonded epoxy pipeline coatings in the presence of direct current interference[J]. Progress in Organic Coatings, 2018, 120: 79-87.

MLA:Qian, Shan, and Y. Frank Cheng. "Degradation of fusion bonded epoxy pipeline coatings in the presence of direct current interference." Progress in Organic Coatings 120 (2018): 79-87.

APA:Qian, S., & Cheng, Y. F. (2018). Degradation of fusion bonded epoxy pipeline coatings in the presence of direct current interference. Progress in Organic Coatings, 120, 79-87.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province