NewsDetails

TPEP Pipes Installation Guide: Best Practices for Underground Pipelines

author:Zhantong time:2025-10-31 17:31:56 Click:130

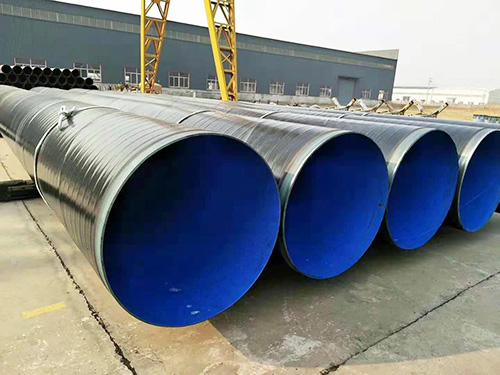

For any buried pipeline project, the reliability and lifespan of the system depend not only on the quality of the materials used but also on how precisely the installation is carried out. TPEP pipes—short for Three-Layer Polyethylene-Coated Steel Pipes—offer an excellent combination of strength, flexibility, and corrosion protection, making them ideal for long-term underground use.

Leading China TPEP pipe manufacturers with bulk supply capabilities have standardized professional installation methods that minimize field errors, improve system safety, and reduce maintenance costs. This guide summarizes those best practices to ensure your pipeline performs flawlessly beneath the surface.

1. Understanding TPEP Pipe Composition

A TPEP pipe features a multilayer anti-corrosion coating that integrates the benefits of both steel and polymer protection:

1.Fusion-Bonded Epoxy (FBE) inner layer – tightly bonded to the steel to resist corrosion.

2.Adhesive middle layer – enhances the chemical bond between epoxy and polyethylene.

3.Polyethylene (PE) outer layer – provides physical defense against soil stress and impact.

This advanced structure allows TPEP pipes to withstand high internal pressures and aggressive soil environments while maintaining leak-tight performance for decades.

2. Advantages of TPEP Pipes for Underground Applications

·Exceptional corrosion and moisture resistance

·High tensile and impact strength suitable for buried conditions

·Low friction internal surface, ensuring smooth fluid transport

·Long operational lifespan, typically exceeding 50 years

·Compatibility with welding and coating repair systems

With advanced coating technology and strict factory inspection, China TPEP pipe suppliers ensure that each pipe produced in bulk lots meets both ISO and AWWA standards.

3. Preparing for Installation

Before placing TPEP pipes into service, several pre-installation checks are essential.

3.1 Site and Trench Inspection

·Verify alignment, trench depth, and soil type to ensure adequate support.

·Remove debris, rocks, and sharp materials that may damage coatings.

·Ensure groundwater levels are managed to prevent flooding during installation.

3.2 Pipe Condition Verification

·Inspect the outer coating for scratches, dents, or exposed metal.

·Confirm size, wall thickness, and factory test certification.

·Store pipes off the ground using padded supports to avoid surface damage.

3.3 Tools and Equipment

Prepare approved lifting devices, coating repair kits, welding tools, and proper protective gear. Using coated steel rollers and non-metallic slings reduces the risk of coating damage during handling.

4. Trench Preparation and Bedding

A stable trench foundation guarantees long-term reliability.

·The trench bottom must be flat and compact, avoiding uneven pressure on the pipe.

·Add a 100–150 mm fine sand or soft soil bedding beneath the pipe.

·In unstable ground, consider reinforced bedding using gravel or geotextile materials.

A well-designed trench not only protects the pipe but also allows for easy inspection and drainage in the future.

5. Pipe Laying and Alignment

5.1 Lowering into Position

Use soft straps or rubber-lined hooks to lower pipes gently into the trench. Avoid rolling or dragging pipes, which may compromise the outer polyethylene layer.

5.2 Alignment and Joint Preparation

·Align each pipe section to maintain a consistent gradient and straight line.

·Use level markers and laser alignment tools for accuracy.

·Check that all pipe ends are clean and dry before welding.

Proper alignment minimizes mechanical stress at joints and enhances the sealing effect during pressurization.

6. Welding and Joint Coating Restoration

TPEP pipes typically have bare steel ends for field welding.

6.1 Welding Process

·Follow qualified procedures such as SMAW, GMAW, or GTAW depending on pipe thickness.

·Shield the weld area from dust and moisture.

·Conduct non-destructive testing (NDT) after welding to verify integrity.

6.2 Recoating the Joint Area

After welding, restore corrosion protection using heat-shrink sleeves, liquid epoxy, or polyethylene repair wraps.

A professional China TPEP pipe manufacturer typically provides complete repair materials and technical support as part of its bulk shipment package.

7. Backfilling and Soil Compaction

Once inspection is complete, carefully backfill the trench:

·Start with soft material or sand up to 300 mm above the pipe.

·Avoid dropping large rocks or using heavy compactors directly over the pipe.

·Compact soil in successive layers to achieve even pressure distribution.

Good compaction prevents soil settlement and mechanical strain on the coating.

8. Pressure Testing and Quality Checks

Before commissioning:

·Perform hydrostatic testing to ensure all joints are leak-free.

·Use holiday detectors to identify coating discontinuities.

·Document and certify all inspection results according to project standards (ISO 21809, AWWA C210).

Periodic maintenance inspections can further extend the lifespan of underground TPEP pipelines.

9. Safety and Environmental Guidelines

·Workers must wear insulated gloves, helmets, and anti-static boots.

·Ventilate welding zones to control fumes.

·Dispose of waste coating and packaging materials responsibly.

Many China manufacturers producing TPEP pipes have shifted toward sustainable production by recycling polyethylene waste and reducing volatile emissions during coating processes.

Conclusion

Installing TPEP pipes correctly is vital for ensuring efficient operation and corrosion-free performance in underground networks. From trench preparation to final coating repair, every step must be performed under strict quality control.

Choosing an experienced China TPEP pipe supplier with bulk manufacturing capability and proven field support ensures long-lasting results and lower life-cycle costs. With the right installation practices, TPEP pipes provide a reliable, environmentally friendly, and cost-effective solution for modern infrastructure systems.

References

GB/T 7714:Li W. Visual Quantitative Characterization of External Corrosion in 3LPE Coated Pipes Based on Microwave Near-Field Reflectometry and Phase Unwrapping[J]. Sensors, 2025, 25(16): 5126.

MLA:Li, Wenjia. "Visual Quantitative Characterization of External Corrosion in 3LPE Coated Pipes Based on Microwave Near-Field Reflectometry and Phase Unwrapping." Sensors 25.16 (2025): 5126.

APA:Li, W. (2025). Visual Quantitative Characterization of External Corrosion in 3LPE Coated Pipes Based on Microwave Near-Field Reflectometry and Phase Unwrapping. Sensors, 25(16), 5126.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province