NewsDetails

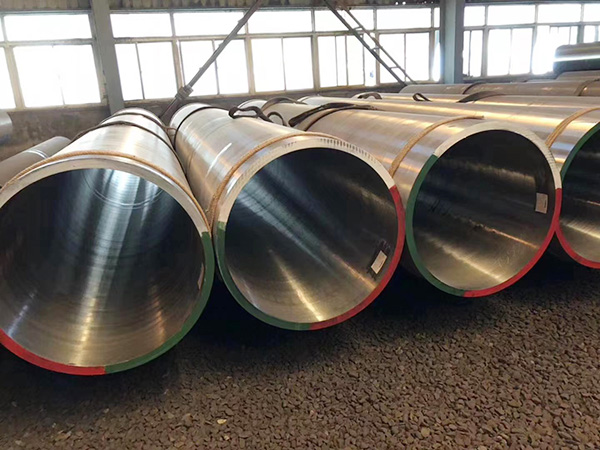

15CrMoG High-Pressure Alloy Tube: High Quality, On-Time Delivery & OEM Service

author:Zhantong time:2026-02-03 18:01:43 Click:135

In the industrial sector, high-pressure alloy tubes are the backbone of critical systems—from power generation to petrochemical processing, where durability, corrosion resistance, and reliability directly impact operational safety and efficiency. Among these, the 15CrMoG high-pressure alloy tube stands out as a preferred choice for high-temperature, high-pressure (HTHP) applications, and we take pride in delivering this premium product with uncompromising quality, on-time delivery, and tailored OEM services to meet your unique project needs.

Why Choose 15CrMoG High-Pressure Alloy Tube?

15CrMoG is a chromium-molybdenum alloy steel tube specifically designed to withstand extreme conditions, making it indispensable in industries that demand high performance under stress. Its unique chemical composition and heat treatment process endow it with exceptional properties that set it apart from ordinary alloy tubes:

·Superior High-Temperature Strength: With excellent creep resistance and oxidation resistance at temperatures up to 550°C, 15CrMoG tubes maintain structural integrity even in long-term high-temperature operation, reducing the risk of deformation or failure.

·Excellent Corrosion & Wear Resistance: The chromium and molybdenum content enhances the tube’s resistance to corrosive media (such as steam, oil, and chemical reagents) and mechanical wear, extending its service life and reducing maintenance costs.

·High Pressure Bearing Capacity: Precision manufacturing and strict quality control ensure that 15CrMoG tubes can withstand high working pressures, making them ideal for boiler tubes, superheater tubes, and high-pressure pipelines in power plants and petrochemical facilities.

·Good Weldability & Processability: The tube can be easily welded, bent, and processed into various shapes without losing its mechanical properties, adapting to diverse installation requirements and project designs.

Uncompromising Quality: Our Commitment to Excellence

Quality is the foundation of our service, and every 15CrMoG high-pressure alloy tube we supply undergoes a rigorous quality control process from raw material selection to final delivery, ensuring it meets international standards (GB/T 5310, ASTM A335, DIN 17175) and your specific requirements:

·Raw Material Inspection: We source high-purity 15CrMoG alloy billets from reputable suppliers, with strict chemical composition and mechanical property testing to eliminate inferior raw materials.

·Precision Manufacturing: Adopting advanced hot-rolling, cold-drawing, and heat treatment technologies, we ensure uniform wall thickness, smooth inner/outer surfaces, and accurate dimensional tolerance (±0.05mm) for every tube.

·Comprehensive Testing: Each batch of tubes undergoes non-destructive testing (NDT), including ultrasonic testing, eddy current testing, and hydraulic pressure testing, as well as mechanical property testing (tensile strength, yield strength, elongation) to guarantee performance.

·Quality Certification: All our 15CrMoG high-pressure alloy tubes are certified by ISO9001, CE, and API, ensuring they comply with global industrial standards and can be used in international projects.

On-Time Delivery: Ensure Your Project Progress is Uninterrupted

We understand that timely delivery is crucial for your project schedule—delays can lead to increased costs and missed deadlines. That’s why we have established a streamlined supply chain and efficient production management system to ensure on-time delivery for every order, no matter the size or complexity:

·Ample Stock: We maintain a large inventory of 15CrMoG high-pressure alloy tubes in various sizes (OD: 10mm-630mm, WT: 1mm-50mm) and specifications, enabling quick delivery for standard orders (3-7 working days).

·Efficient Production Capacity: Our advanced production lines have a monthly output of 5000+ tons, allowing us to handle large custom orders efficiently and deliver them within the agreed timeframe (15-30 working days).

·Professional Logistics Cooperation: We cooperate with well-known international logistics companies (DHL, FedEx, Maersk) to provide fast, safe, and reliable shipping services, with real-time logistics tracking so you can monitor your order’s progress at any time.

·Emergency Order Support: For urgent orders, we prioritize production and arrange expedited shipping to ensure your project is not interrupted, providing you with peace of mind.

Tailored OEM Service: Meet Your Unique Requirements

Every project has unique needs, and we don’t believe in a “one-size-fits-all” approach. Our professional OEM service is designed to customize 15CrMoG high-pressure alloy tubes according to your specific specifications, helping you achieve optimal performance and cost-effectiveness:

·Custom Sizes & Shapes: We can produce tubes with custom outer diameter, wall thickness, length, and shapes (U-bend, S-bend, etc.) to fit your project’s installation space and design requirements.

·Special Surface Treatment: Provide custom surface treatment services such as galvanizing, pickling, passivation, and anti-corrosion coating to enhance the tube’s durability in harsh environments.

·Customized Packaging: According to your shipping and storage needs, we offer customized packaging (wooden cases, steel frames, waterproof packaging) to prevent damage during transportation.

·Technical Support & Customization Consultation: Our team of professional engineers provides one-on-one technical consultation, helping you determine the best specifications and customization options for your project, ensuring the tube meets your exact performance requirements.

Our Advantage: Why Partner With Us?

When you choose us as your 15CrMoG high-pressure alloy tube supplier, you’re not just getting a product—you’re getting a reliable partner committed to your success. Here’s what sets us apart:

✅ Factory Direct Pricing: No middlemen, offering competitive prices while ensuring high quality.

✅ Professional Team: Experienced engineers and sales team provide full-cycle service from consultation to after-sales.

✅ Global Supply Capacity: We have exported 15CrMoG tubes to 50+ countries (Europe, America, Southeast Asia, the Middle East) and have rich experience in international trade.

✅ After-Sales Guarantee: We provide a 12-month quality guarantee. If there is any quality problem with the product, we will provide free replacement or refund.

Contact Us Today for Your 15CrMoG High-Pressure Alloy Tube Needs

Whether you need standard 15CrMoG high-pressure alloy tubes or customized OEM solutions, we are here to help. With our high-quality products, on-time delivery, and professional service, we will be your trusted partner for industrial high-pressure tube solutions. Send us an inquiry now to get a free quote, technical consultation, or customize your order. We look forward to cooperating with you!

References

GB/T 7714:Peritectic Solidification Characteristics and Mechanism of 15CrMoG Steel. Acta Metallurgica Sinica

MLA:Mechanical Properties and High-Temperature Creep Behavior of 15CrMoG High-Pressure Alloy Tubes for Power Plant Applications. Journal of Materials Engineering and Performance

APA:Corrosion and Wear Resistance of 15CrMoG Alloy Steel Tubes in Petrochemical Environments. Corrosion Science and Protection Technology

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province