NewsDetails

Advantages of TPEP Pipes in Long-Distance Water Transmission Systems

author:Zhantong time:2025-12-19 17:23:22 Click:94

The Growing Demand for Reliable Water Transmission Pipelines

Long-distance water transmission systems play a critical role in urban development, agriculture, and industrial water supply. These systems require pipelines that can withstand internal pressure, external loads, and environmental challenges over extended service life. Among modern pipeline solutions, TPEP pipes have gained attention for their balanced performance and durability.

From a manufacturing perspective, TPEP pipes are designed through advanced production processes to meet the technical demands of large-scale water transmission projects. From an engineering perspective, their structural advantages help improve system reliability while reducing long-term maintenance requirements. This article examines the key benefits of using TPEP pipes in long-distance water transmission systems.

Understanding the Structure of TPEP Pipes

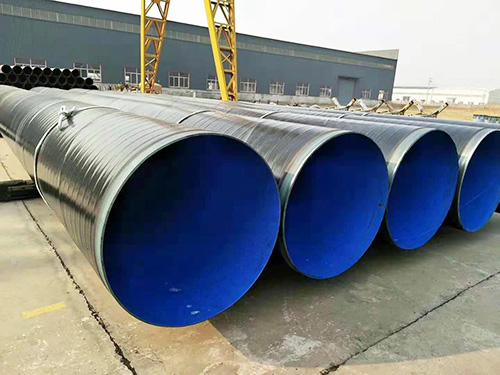

TPEP pipes typically feature a multi-layer structure that combines steel strength with enhanced internal and external protective layers. This composite design contributes to both mechanical performance and corrosion resistance.

Core structural features include:

·Steel pipe core for high strength

·Protective internal lining to reduce friction

·External coating designed to resist soil and moisture exposure

Manufacturers rely on controlled production methods to ensure consistent layer bonding and uniform performance across bulk supply batches.

High Mechanical Strength for Long-Distance Applications

One of the primary advantages of TPEP pipes is their high mechanical strength. Long-distance water transmission often involves high internal pressures and varying terrain conditions.

The steel core provides:

·Resistance to internal pressure

·Ability to handle external loads

·Structural stability over long pipeline routes

These properties allow TPEP pipes to perform reliably in large-scale installations where pipeline integrity is essential.

Excellent Corrosion Resistance

Corrosion is a major concern in water transmission systems, especially for buried pipelines exposed to soil, moisture, and chemical elements.

TPEP pipes address this challenge through:

·Internal coatings that protect against water-induced corrosion

·External protective layers that shield against soil corrosion

From a production standpoint, manufacturers carefully control coating application to ensure uniform thickness and strong adhesion, particularly for pipes supplied in bulk quantities.

Reduced Hydraulic Resistance and Improved Flow Efficiency

The internal lining of TPEP pipes is designed to provide a smooth surface that minimizes hydraulic resistance. Reduced friction translates into improved flow efficiency over long distances.

Benefits include:

·Lower energy consumption for pumping

·More stable flow rates

·Reduced operational costs

For long-distance systems, these efficiency gains can significantly impact overall project economics.

Adaptability to Complex Installation Conditions

Long-distance water transmission routes often pass through varied terrain, including urban areas, agricultural land, and uneven ground.

TPEP pipes offer:

·Good adaptability to bending and alignment requirements

·Compatibility with standard installation techniques

·Reliable performance under varying environmental conditions

Manufacturers design TPEP pipes to meet installation demands while maintaining structural integrity throughout the production process.

Long Service Life and Reduced Maintenance

Durability is a key consideration for water transmission infrastructure. TPEP pipes are engineered for long service life through a combination of material selection and protective coatings.

Advantages include:

·Reduced frequency of repairs

·Lower long-term maintenance costs

·Stable performance over extended operating periods

Consistent production quality ensures that these benefits are maintained across large pipeline projects.

Suitability for Large-Scale and Bulk Supply Projects

Large water transmission projects require reliable bulk supply of pipes with consistent specifications. TPEP pipe manufacturers are structured to support:

·High-volume production capacity

·Uniform quality across production batches

·Stable delivery schedules

This capability is critical for projects with strict timelines and extensive pipeline networks.

Environmental and Operational Benefits

TPEP pipes contribute to environmental and operational efficiency by reducing leakage risk and improving energy efficiency. Their long service life also supports sustainable infrastructure development by minimizing material replacement and waste.

From a manufacturing perspective, optimizing production processes helps reduce material loss and ensures efficient resource utilization.

Conclusion: Why TPEP Pipes Are Ideal for Long-Distance Water Transmission

TPEP pipes offer a combination of mechanical strength, corrosion resistance, flow efficiency, and long-term reliability that makes them well suited for long-distance water transmission systems. Their composite structure and controlled manufacturing processes provide consistent performance in demanding environments.

When TPEP pipes are produced through stable production systems and supplied in bulk for large-scale projects, they support efficient installation, reliable operation, and sustainable infrastructure development. For modern water transmission needs, TPEP pipes represent a practical and dependable solution.

References

GB/T 7714:Najafi M, Gokhale S B. Trenchless technology: Pipeline and utility design, construction, and renewal[J]. (No Title), 2005.

MLA:Najafi, Mohammad, and Sanjiv B. Gokhale. "Trenchless technology: Pipeline and utility design, construction, and renewal." (No Title) (2005).

APA:Najafi, M., & Gokhale, S. B. (2005). Trenchless technology: Pipeline and utility design, construction, and renewal. (No Title).

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province