NewsDetails

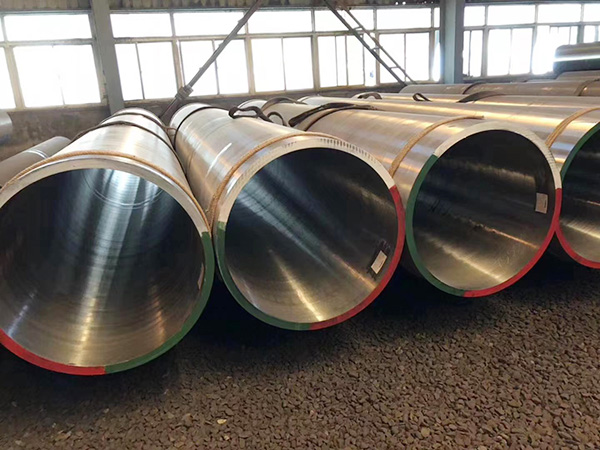

Heat Expansion Behavior of Seamless Steel Tubes Under Thermal Stress

author:Zhantong time:2025-12-17 16:20:13 Click:108

Thermal Stress and Its Importance in Seamless Steel Tubes

Seamless steel tubes are widely used in industries where temperature variation is unavoidable, such as power generation, petrochemical processing, mechanical engineering, and structural applications. Under thermal stress, these tubes undergo expansion and contraction that directly affect system safety, dimensional stability, and long-term performance.

From a manufacturing perspective, understanding the heat expansion behavior of seamless steel tubes is essential during production planning and quality control. From an engineering perspective, accurate knowledge of thermal behavior helps designers and installers prevent deformation, leakage, or premature failure. This article provides a comprehensive overview of how seamless steel tubes respond to thermal stress and why this behavior matters in real-world applications.

Basic Principles of Thermal Expansion in Steel

Thermal expansion refers to the tendency of materials to change dimensions when exposed to temperature changes. For steel, this behavior is generally linear within typical operating temperature ranges.

Key factors influencing thermal expansion include:

·Material composition

·Temperature range

·Tube length and wall thickness

·Constraint conditions during operation

Seamless steel tubes, produced through controlled manufacturing processes, exhibit uniform expansion characteristics due to their consistent microstructure and absence of welded seams.

Material Composition and Its Effect on Expansion

The chemical composition of steel plays a critical role in determining thermal expansion behavior. Carbon content, alloying elements, and heat treatment conditions all influence how seamless steel tubes respond to heat.

Low-alloy and carbon steel tubes generally show predictable expansion patterns, while alloyed grades may exhibit slightly different coefficients of expansion. During production, manufacturers carefully control material chemistry to ensure stable and repeatable thermal performance, particularly for bulk supply intended for high-temperature environments.

Role of Seamless Manufacturing in Thermal Stability

Unlike welded tubes, seamless steel tubes are formed without longitudinal weld seams. This manufacturing advantage contributes to:

·Uniform grain structure

·Consistent mechanical properties

·Reduced stress concentration points

As a result, seamless steel tubes tend to expand more evenly under thermal stress. This uniform behavior is especially important in systems where tubes are subjected to repeated heating and cooling cycles.

Tube Dimensions and Heat Expansion Behavior

Length and Linear Expansion

Tube length has a direct impact on total thermal expansion. Longer seamless steel tubes experience greater absolute expansion when temperature rises, even if the expansion coefficient remains constant.

In large-scale installations, this cumulative expansion must be considered during design. Manufacturers often provide dimensional consistency across production batches, allowing engineers to predict expansion behavior more accurately.

Wall Thickness and Structural Response

While wall thickness does not significantly change the expansion coefficient, it affects how thermal stress is distributed across the tube structure. Thicker walls can better resist deformation but may also retain heat longer, influencing cooling rates.

During production, wall thickness tolerance is tightly controlled to ensure consistent performance, particularly in bulk manufacturing scenarios.

Thermal Stress in Constrained vs. Free Conditions

Seamless steel tubes rarely operate in completely free conditions. In many systems, tubes are fixed, clamped, or embedded within structures.

·Free expansion allows tubes to extend without generating internal stress.

·Constrained expansion can produce significant thermal stress, potentially leading to bending, buckling, or fatigue over time.

Understanding these conditions is critical during system design. Manufacturers often consider typical application constraints when producing tubes for high-temperature service.

Cyclic Heating and Long-Term Performance

Repeated thermal cycling can gradually affect seamless steel tubes, even if individual temperature changes are within acceptable limits.

Potential long-term effects include:

·Accumulation of residual stress

·Microstructural changes

·Reduced fatigue resistance

High-quality production processes and material selection help minimize these risks, especially for tubes supplied in bulk to industries with continuous or cyclic thermal loads.

Engineering Strategies to Manage Thermal Expansion

To accommodate heat expansion, engineers commonly use:

·Expansion joints

·Flexible supports

·Sliding or guided mounts

While these strategies are implemented at the system level, their effectiveness depends on predictable tube behavior. Seamless steel tubes manufactured with consistent properties enable more reliable thermal management solutions.

Quality Control and Production Considerations

From a manufacturer’s standpoint, ensuring predictable thermal expansion behavior starts with strict quality control during production.

Key measures include:

·Chemical composition verification

·Dimensional accuracy checks

·Mechanical property testing

·Batch traceability for bulk supply

These practices help ensure that seamless steel tubes perform as expected under thermal stress across different projects and operating conditions.

Conclusion: Why Thermal Expansion Knowledge Matters

The heat expansion behavior of seamless steel tubes under thermal stress is a fundamental consideration in high-temperature applications. Material composition, manufacturing method, tube dimensions, and operating conditions all influence how tubes respond to heat.

When seamless steel tubes are produced through controlled manufacturing processes and supplied in bulk with consistent quality, their thermal behavior becomes predictable and manageable. This reliability supports safer designs, longer service life, and improved system performance across a wide range of industrial applications.

References

GB/T 7714:Callister Jr W D, Rethwisch D G. Materials science and engineering: an introduction[M]. John wiley & sons, 2020.

MLA:Callister Jr, William D., and David G. Rethwisch. Materials science and engineering: an introduction. John wiley & sons, 2020.

APA:Callister Jr, W. D., & Rethwisch, D. G. (2020). Materials science and engineering: an introduction. John wiley & sons.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province