NewsDetails

Long-Term Durability of TPEP Pipes in Harsh Environments

author:Zhantong time:2025-10-15 21:04:34 Click:168

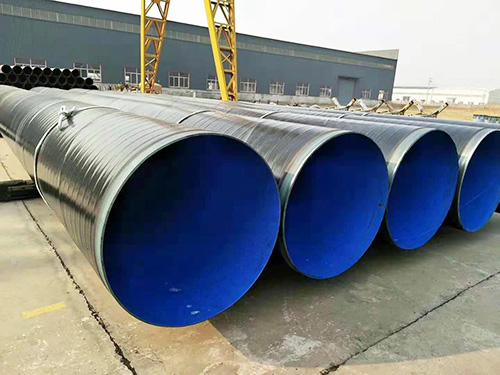

When operating in extreme conditions—such as high salinity coastal zones, arid deserts, or chemically aggressive soils—the choice of pipeline material can determine the safety and efficiency of an entire project. TPEP Pipes (Three-Layer Polyethylene Coated Pipes) have become a preferred option because they combine the structural strength of steel with advanced polyethylene coatings that resist corrosion, wear, and chemical attack.

Working with a China manufacturer that can demonstrate bulk supply capability provides assurance of steady delivery, standardized quality, and compliance with global requirements. This makes TPEP pipes a strategic solution for infrastructure projects facing the toughest environmental challenges.

Why Durability Is Critical

Protection Against Corrosion

Moisture, salt, and acidic soils are leading causes of pipeline degradation. Unlike uncoated steel, TPEP pipes use a polyethylene coating that prevents direct exposure to corrosive elements, significantly extending service life.

Structural Reliability

Since TPEP pipes retain the steel core, they maintain excellent load-bearing and pressure resistance properties. This balance between mechanical strength and surface protection makes them ideal for pipelines subjected to both environmental stress and high operational pressure.

Chemical Resistance

In areas where soil or groundwater contains industrial contaminants, traditional materials may degrade quickly. TPEP pipes withstand chemical intrusion, minimizing the risk of leaks and ensuring long-term performance.

Design and Selection Considerations

·Coating Thickness – Uniform application of the polyethylene layer is essential. Buyers should verify supplier reports that demonstrate consistent coating quality.

·Wall Strength and Dimensions – Choosing the right thickness balances pressure demands with weight efficiency, particularly important for long-distance transmission lines.

·International Standards – Certification under ISO, API, or ASTM confirms that pipes meet global engineering expectations.

·Handling and Logistics – Proper packaging and shipment procedures from trusted China suppliers reduce damage risks during transport and installation.

Applications in Harsh Conditions

·Energy Transmission: Oil and gas pipelines benefit from their combined pressure resistance and anti-corrosion layers.

·Municipal Water Supply: Their protective coatings prevent rust, ensuring clean water transport in cities and towns.

·Coastal Projects: Ports, desalination plants, and offshore installations demand corrosion-proof pipelines, making TPEP pipes highly suitable.

·Industrial Facilities: From chemical factories to mining operations, these pipes ensure safe handling of fluids in aggressive environments.

Advantages of Partnering with a China Manufacturer

Verified Bulk Supply

Infrastructure projects often require massive quantities of pipe. Choosing a China manufacturer that can prove bulk supply capacity assures consistent quality and dependable delivery schedules. This capability is especially valuable for projects with tight deadlines.

Competitive Pricing and Custom Options

Chinese suppliers often provide flexible specifications—diameter, wall thickness, coating levels—at highly competitive costs. This enables engineers to meet project requirements without overspending.

Documentation and Compliance

Established manufacturers provide full inspection reports, quality certificates, and international compliance documents. This transparency reduces procurement risk and strengthens confidence in the material supply chain.

Common Issues and Solutions

·Transport Scratches – Protective coatings may be damaged if not packed properly. Reliable suppliers use reinforced packaging methods to safeguard product integrity.

·Variable Soils and Climates – Engineers should request coating designs adapted to local ground and weather conditions.

·Maintenance Practices – Although TPEP pipes are designed for longevity, scheduled inspections allow early detection of potential wear.

Future Development of TPEP Pipes

Ongoing advances in polymer chemistry, coating techniques, and quality inspection systems will further enhance the lifespan of TPEP pipes. As global investment in energy, water, and industrial infrastructure rises, the demand for these pipes—especially in harsh environments—is projected to increase. China suppliers are expected to remain at the forefront by scaling up production and adopting newer coating technologies.

Conclusion

In projects where long-term reliability is critical, TPEP Pipes stand out as a superior choice. Their corrosion resistance, structural integrity, and chemical durability make them well-suited for harsh conditions. By sourcing directly from a China manufacturer with proven bulk supply records, project managers secure both consistent product quality and reliable delivery.

For organizations seeking durable and cost-effective pipeline solutions, TPEP pipes offer a combination of strength and resilience that ensures safe, efficient operation for decades.

References

GB/T 7714:Li W. Visual Quantitative Characterization of External Corrosion in 3LPE Coated Pipes Based on Microwave Near-Field Reflectometry and Phase Unwrapping[J]. Sensors (Basel, Switzerland), 2025, 25(16): 5126.

MLA:Li, Wenjia. "Visual Quantitative Characterization of External Corrosion in 3LPE Coated Pipes Based on Microwave Near-Field Reflectometry and Phase Unwrapping." Sensors (Basel, Switzerland) 25.16 (2025): 5126.

APA:Li, W. (2025). Visual Quantitative Characterization of External Corrosion in 3LPE Coated Pipes Based on Microwave Near-Field Reflectometry and Phase Unwrapping. Sensors (Basel, Switzerland), 25(16), 5126.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province