NewsDetails

TPEP Pipes for Industrial Water Systems: Benefits and Installation Tips

author:Zhantong time:2025-09-13 10:38:07 Click:151

The Role of TPEP Pipes in Modern Water Infrastructure

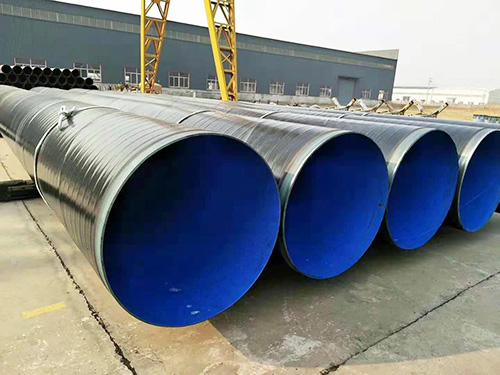

Selecting the right pipeline material is crucial for industrial projects, especially where water transport is continuous and demanding. TPEP Pipes (Three-Layer Polyethylene Coated Pipes) have gained wide adoption thanks to their unique balance of mechanical strength and protective layers. Whether used in power generation, chemical processing, or large water distribution, these pipes offer lasting reliability with reduced maintenance needs.

What Makes TPEP Pipes Unique?

TPEP Pipes are engineered with a triple-layer design that maximizes both durability and protection:

·Steel Core: Acts as the backbone, providing structural integrity and high load capacity.

·Epoxy Inner Lining: Creates a corrosion-resistant, smooth channel for water flow.

·Polyethylene Outer Coating: Defends the pipe from soil chemicals, physical wear, and environmental stress.

This three-tier system ensures that TPEP Pipes remain efficient and resilient even under challenging industrial water system conditions.

Key Benefits of TPEP Pipes in Industrial Applications

1. Outstanding Corrosion Resistance

Industrial water often carries minerals, chemicals, and varying pH levels that attack unprotected steel. With an epoxy interior barrier, TPEP Pipes drastically reduce internal corrosion and prolong service life.

2. Strength Under Pressure

The steel body provides exceptional tolerance to internal water pressure and external loads, making these pipes ideal for high-demand facilities.

3. Longevity and Cost Savings

By minimizing leaks and wear, TPEP Pipes reduce the frequency of replacements and repairs, ensuring lower lifetime costs for industrial operators.

4. Hydraulic Efficiency

The smooth epoxy lining lowers friction, ensuring consistent water flow and reducing the energy required for pumping.

5. Versatility Across Applications

From small-diameter pipelines in localized systems to large conduits in regional networks, TPEP Pipes can be customized to fit different industrial needs.

Practical Installation Tips for TPEP Pipes

Handle with Care

Store pipes on level surfaces and shield them from sharp edges and direct UV exposure to maintain coating integrity.

Pay Attention to Jointing

Welding should be done carefully, with protective measures applied afterward to restore full corrosion resistance at the joints.

Prepare the Trench Properly

Uniform bedding prevents uneven stress points, helping to extend the lifespan of the installed pipeline.

Inspect Coating Before Backfilling

Any damage to the protective layers should be repaired immediately using approved materials to preserve performance.

Test Before Commissioning

Hydrostatic pressure tests confirm that the system is leak-free and ready for long-term operation with TPEP Pipes.

Industrial Water System Applications

·Cooling Systems in power plants

·Process Water Transport in industrial facilities

·Wastewater Conveyance in treatment plants

·Regional Water Supply networks requiring reliability and strength

Environmental Contribution of TPEP Pipes

Durability is not only an economic benefit but also an environmental one. TPEP Pipes reduce the need for frequent replacements, conserving raw materials and lowering carbon footprints. Additionally, their steel base can be recycled, aligning with sustainability goals in modern infrastructure.

Conclusion

Industrial water systems require pipes that balance strength, resistance, and long-term reliability. TPEP Pipes achieve this through their three-layer construction, combining the toughness of steel with the protective benefits of epoxy and polyethylene coatings.

By following best practices during installation, industries can unlock decades of dependable service, reduced maintenance costs, and improved operational efficiency. As water systems become more critical in industrial growth, choosing TPEP Pipes ensures a sustainable and resilient foundation for the future.

References

GB/T 7714:Bigdeli F, Javidi M, Pakshir M. A comparative study of mechanical properties and corrosion behavior of fusion-bonded epoxy and liquid epoxy coatings and their service life in drill pipe applications[J]. Materials Research Express, 2021, 8(2): 025506.

MLA:Bigdeli, Faryad, Mehdi Javidi, and Mahmoud Pakshir. "A comparative study of mechanical properties and corrosion behavior of fusion-bonded epoxy and liquid epoxy coatings and their service life in drill pipe applications." Materials Research Express 8.2 (2021): 025506.

APA:Bigdeli, F., Javidi, M., & Pakshir, M. (2021). A comparative study of mechanical properties and corrosion behavior of fusion-bonded epoxy and liquid epoxy coatings and their service life in drill pipe applications. Materials Research Express, 8(2), 025506.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province