NewsDetails

What Are TPEP Pipes? A Complete Introduction for Industrial Projects

author:Zhantong time:2025-12-10 16:36:55 Click:181

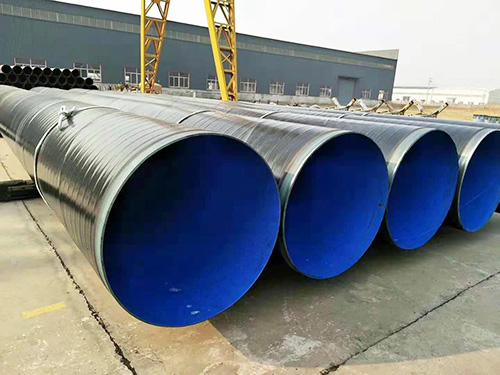

TPEP Pipes have become one of the most dependable pipeline solutions across modern industrial and municipal projects. Known for their tough structure and remarkable anti-corrosion properties, TPEP Pipes play a crucial role in systems that require long-distance, stable, and efficient fluid transportation. From the start, understanding how these pipes are engineered will help project designers and contractors make better decisions that enhance system reliability.

With the increasing demand for durability and cost-effective infrastructure materials, TPEP Pipes are now recognized as a highly versatile option, suitable for both new installations and large-scale upgrades. This article provides a full overview of their structure, performance characteristics, and engineering value across multiple industries.

What Makes TPEP Pipes Unique?

TPEP stands for Thermo-Plastic and Epoxy-Coated Pipes, a multi-layer structure designed to withstand physical stress, environmental impact, and chemical corrosion. These pipes are built through a composite approach:

·A steel base that carries internal and external pressure

·An epoxy inner lining that creates a smooth, anti-corrosive passage

·A thermoplastic outer shield that absorbs physical impacts and prevents degradation

This form of layered construction is the key reason TPEP Pipes outperform many single-material pipeline designs.

Core Advantages of TPEP Pipes

1. Exceptional Corrosion Prevention

The inner epoxy layer creates a dense, protective coating that resists rust, chemical erosion, and scaling. This makes TPEP Pipes particularly suitable for underground installations, chemically active environments, and areas with unstable soil conditions.

2. Smooth Internal Flow Path

Fluid friction is minimized thanks to the uniform inner coating, which supports continuous, stable flow. This is essential for long-distance water transmission, reducing pumping energy and improving overall system efficiency.

3. Robust Structural Strength

The steel core provides the compression and load-bearing capacity needed for high-pressure industrial applications. This durability is especially valuable in engineering scenarios where pipes must endure heavy ground loads, vehicle movement, or seismic activity.

4. Wide Environmental Adaptability

TPEP Pipes maintain performance in extreme temperatures, corrosive soils, and complex topography, supporting their use in diverse project types.

Where TPEP Pipes Are Commonly Applied

Water Transmission Projects

Large infrastructure projects rely on TPEP Pipes to maintain safe, steady, long-distance water delivery. Their corrosion resistance and low-maintenance nature make them the preferred option for municipal systems.

Industrial Fluid Lines

Factories, processing plants, and production facilities utilize TPEP Pipes to manage fluids that must remain uncontaminated and safely transported.

Fire Safety Networks

Their high pressure resistance and thermal stability support long-term use in fire suppression systems for large buildings, warehouses, and industrial complexes.

Wastewater and Sewage Systems

The epoxy interior prevents sediment buildup, reducing blockages and providing sanitary flow pathways.

Technical Strengths of TPEP Pipes in Engineering Projects

Long Service Life

The multi-layer system delivers long-term performance with minimal maintenance. Epoxy lining protects against chemical damage, while the outer thermoplastic shield guards against mechanical harm.

Reduced Operational Expenses

The low-friction interior and stable structure reduce energy and maintenance costs throughout the pipeline's lifecycle.

Flexible Installation Options

Based on project needs, TPEP Pipes can be welded or assembled using mechanical joints. This adaptability supports both site-based installations and efficient factory-level Production.

Selecting a Capable Manufacturer for TPEP Pipes

High-quality TPEP Pipes depend on reliable manufacturers with strict Production standards and proven bulk-supply capabilities. A trustworthy supplier typically provides:

·Consistent coating thickness control

·Full-scale mechanical, pressure, and adhesion testing

·Customizable specifications for different industrial scenarios

·Technical assistance before and after installation

Choosing a capable factory ensures that every batch of TPEP Pipes works seamlessly within engineering requirements.

TPEP Pipes and Sustainable Engineering

As the construction and industrial sectors shift toward more sustainable solutions, TPEP Pipes align well with modern development goals. Their structural integrity reduces replacement frequency, their smooth internal surface lowers energy usage, and their long-term resistance against corrosion cuts down on waste and repair costs.

The combination of durability, performance, and environmental efficiency positions TPEP Pipes as an ideal choice for forward-looking industrial infrastructure.

Conclusion: Why TPEP Pipes Are Essential for Large Engineering Projects

TPEP Pipes stand out as a reliable solution for long-distance transportation systems in industrial, municipal, and commercial infrastructure. Their hybrid design offers remarkable corrosion resistance, low friction, and long-term stability—features that help reduce operational costs and enhance project durability. Working with experienced manufacturers that support high-volume Production ensures consistent quality and smooth project execution.

As the demand for robust, efficient, and sustainable pipeline materials continues to rise, TPEP Pipes will remain a critical component for modern engineering and industrial projects.

References

GB/T 7714:Bai Y, Bai Q. Subsea pipeline integrity and risk management[M]. Gulf Professional Publishing, 2014.

MLA:Bai, Yong, and Qiang Bai. Subsea pipeline integrity and risk management. Gulf Professional Publishing, 2014.

APA:Bai, Y., & Bai, Q. (2014). Subsea pipeline integrity and risk management. Gulf Professional Publishing.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 15231788966

—— Email:info@zhantongpipe.com

—— Url:https://www.zhantongpipe.com

—— Address:Mengcun Hui Autonomous County, Cangzhou City, Hebei Province